Epoxy pipes are manufactured by wrapping fiberglass around a steel mold in a precise, spiral pattern. These composite pipes, with their unique capabilities, offer customers an engineered solution to many challenges at various project stages. Pipe Industry Co., Ltd. has the significant advantage of being able to design all engineering aspects related to these pipes. Therefore, the company handles each project individually to ensure that all designs and inputs comply with the project’s conditions and requirements. Furthermore, this advantage is achieved in a reliable and documented manner by providing various documents that explain and clarify all stages of these products, from the selection of raw materials through the manufacturing steps to the installation and maintenance of these products. All of these processes are based on previous experience of more than 23 years, during which we have completed more than 3,000 kilometers of pipes and more than 300,000 attached pieces.

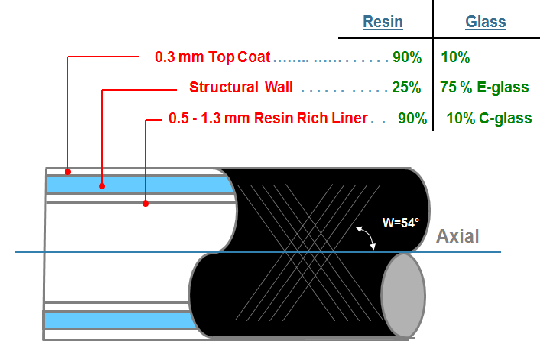

Glass Fiber pipes layers

Internal layer

This layer is in direct contact with the fluid being transported in the pipe, so it is designed to ensure maximum resistance to the chemical reaction resulting from the fluid. Furthermore, this layer offers a particularly smooth inner surface, as it consists of a lower percentage of fiberglass compared to the amount of epoxy.

Intermediate layer

Its function is to provide resistance to stresses due to operating conditions (internal and/or external pressure, bending force due to external loads, etc.). The thickness of this layer determines the strength and durability of the pipe.

Foreign Ministry layer

It is usually 0.3 mm thick and consists of an epoxy compound as the primary component. This layer protects the middle layer and its fiberglass contents, leaving the outer surface of the pipe completely free of protruding fibers, giving it a perfect shape. The primary purpose of this layer is to provide protection against ultraviolet rays from the sun.